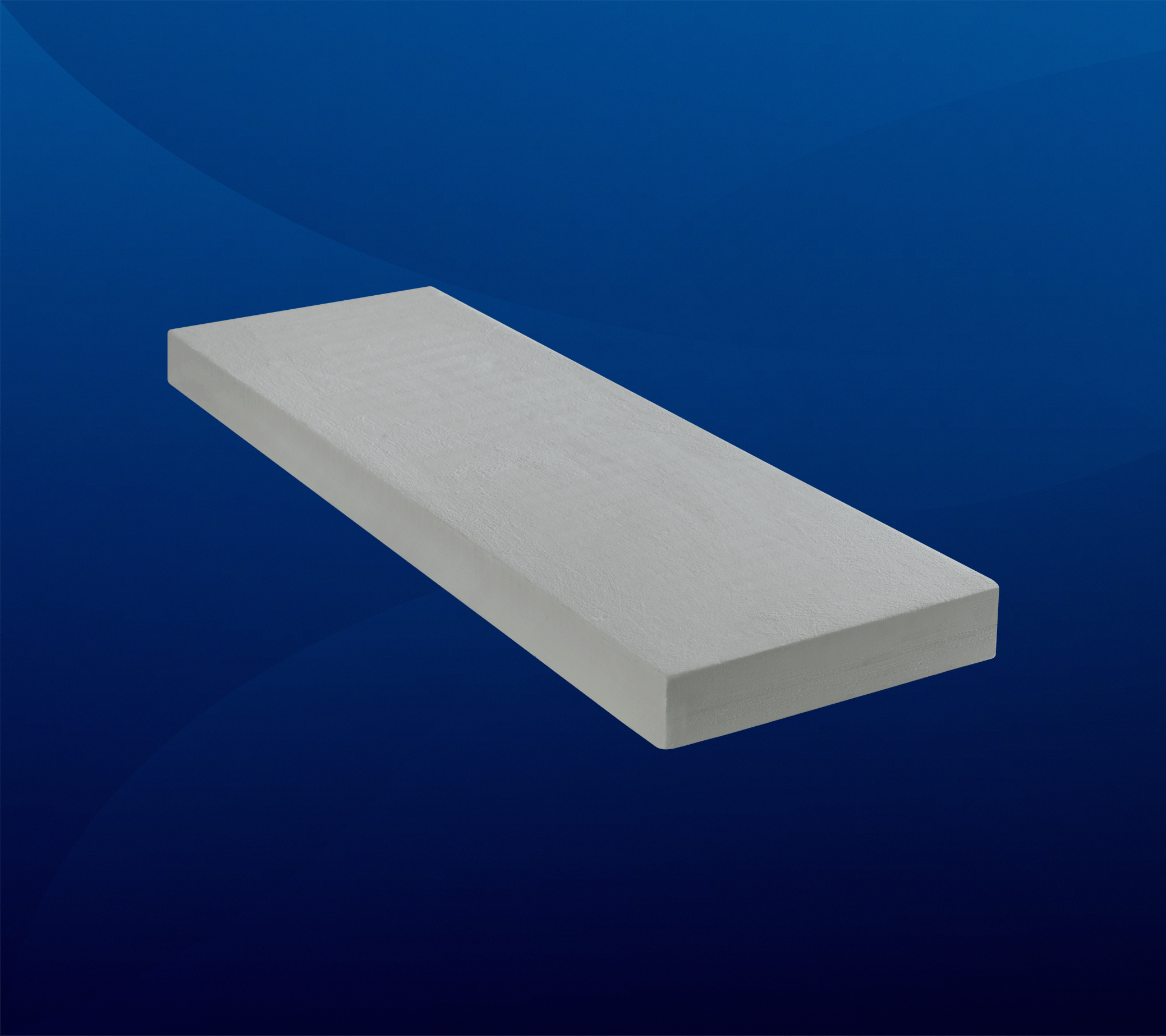

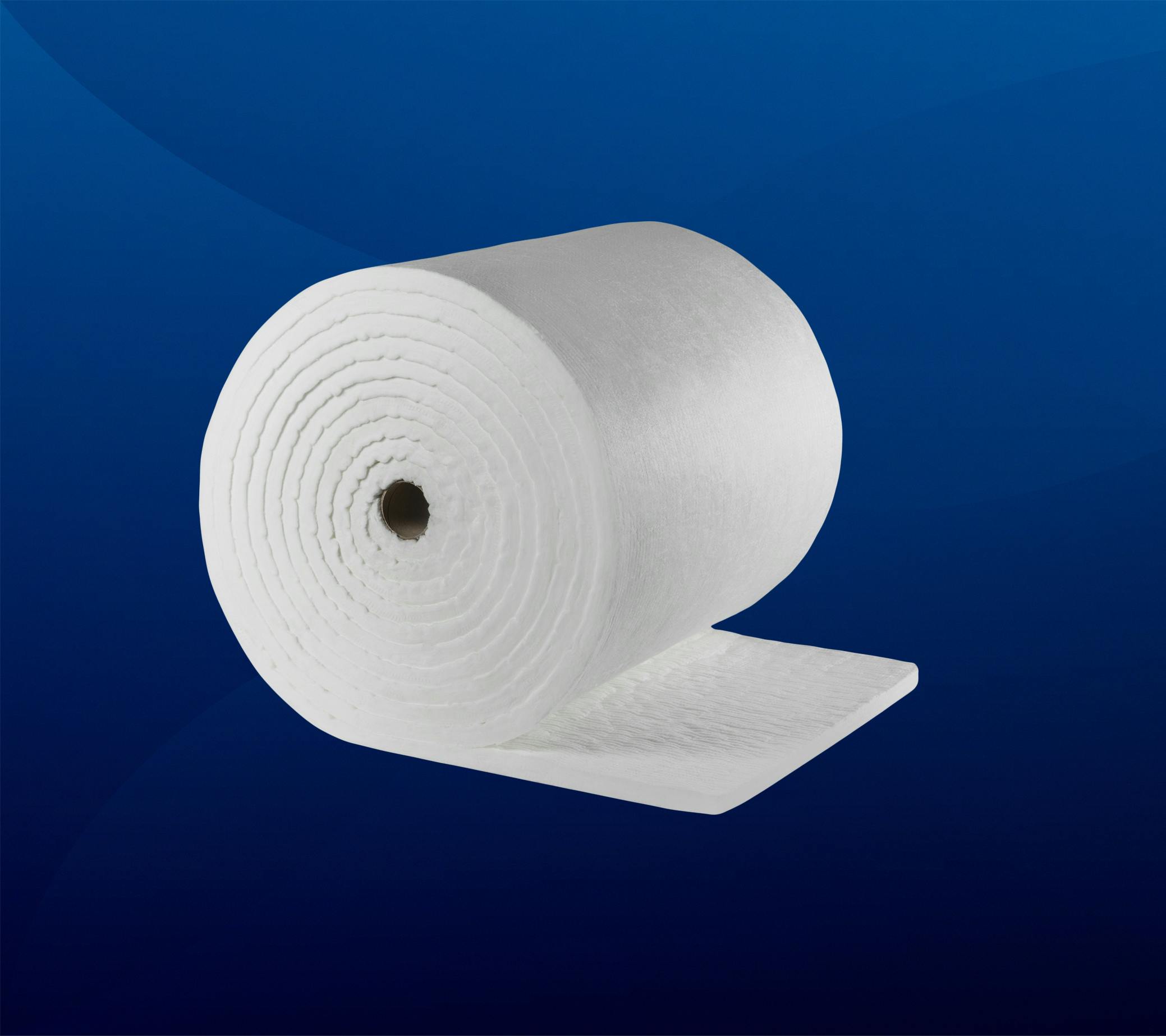

MaxBoard LD 3000 has the highest temperature rating of any NUTEC board product. Formulated from a blend of ceramic and mullite fibers that create an excellent high-temperature insulation board with low thermal shrinkage and excellent high-temperature stability.

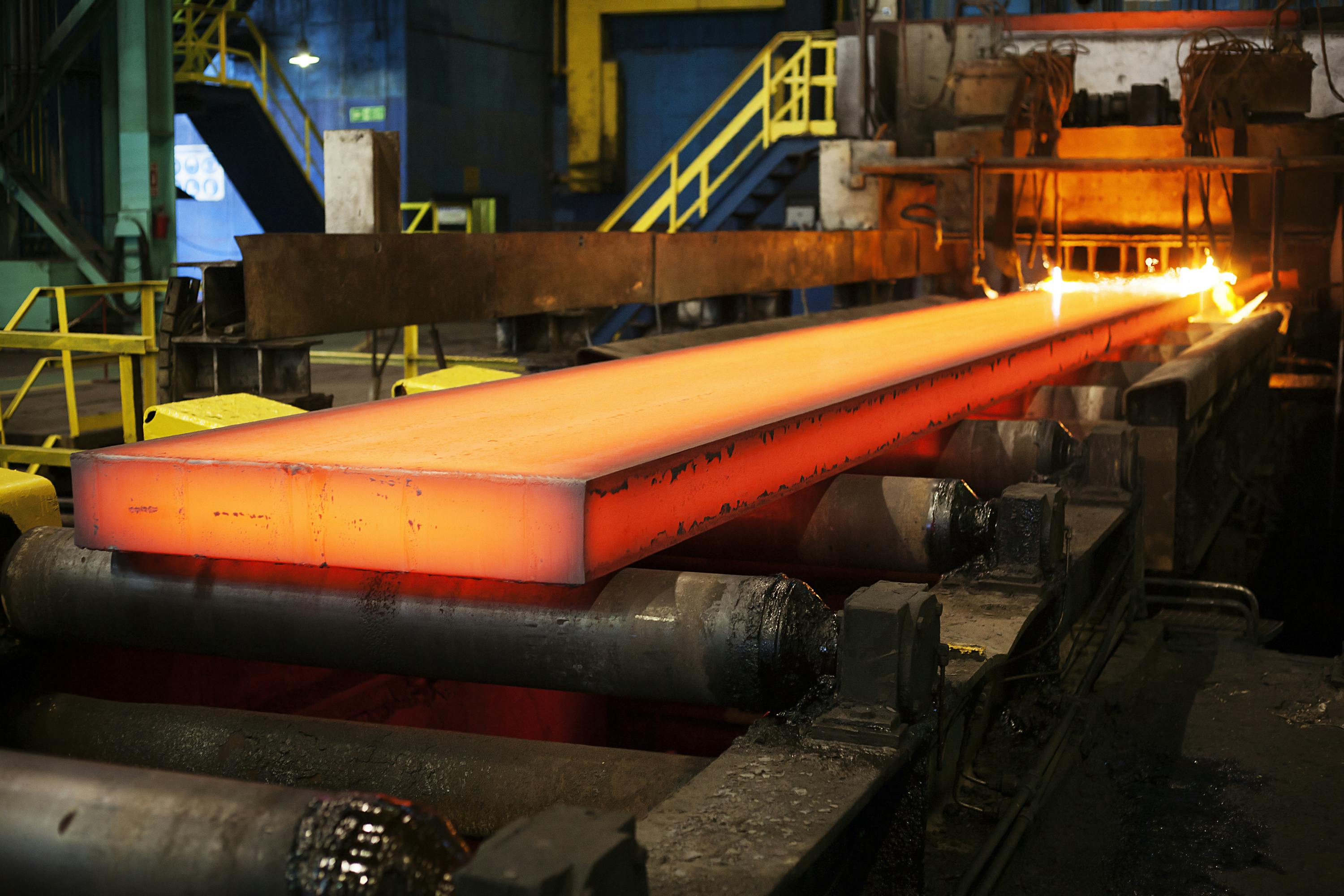

MaxBoard products are processed from alumina and silica blends. Are made to resist high velocities, high vibrations, erosive forces and mechanical stresses. The high modulus of rupture and uniform density makes these boards ideally suited for cutting or machining.

These products proved low thermal conductivity, low heat loss and heat storage. Vacuum Formed Boards are ideal for furnace linings, boiler ducts and stacks.